Start your journey into sustainable manufacture

We can work with you to develop sustainable alternatives to non-recyclables, man-made and polluting fibre in existing components and to develop exciting new sustainable product ranges that listen to the wants of the end-user.

Developing fabrics sustainably covers not only raw materials and processes but also logistics. John Spencer Textiles is close to excellent transport links for ease of delivery, and all fabrics are woven and finished in the local region, so can sometimes travel no more than a mile during manufacture. You can be sure of the fact that when you say ‘Made in Britain’, your fabrics genuinely are!

We use FSC approved cardboard to transport your products and try to minimise the amount of plastic and so bulk-pack items. In some cases, we can hold stock for you and despatch as needed. Please talk to a member of the team about your individual needs.

As a part of our commitment to ‘always improve’, our mill has been fitted with 175 solar panels. Saving 375 tonnes of Co2 and generating 945,000kwh of electricity over 25 years, allowing us to power all of our offices on greener energy and gives a bit more back to the grid. We aim to continue to evaluate these areas where we can do better and make changes as we develop the business.

GET IN TOUCH

If you have any questions about our sustainable manufacturing or if you would like to talk to a member of the team about a specific project, no matter the size please contact us, we’re always happy to help.

Welcome to our John Spencer Blog

John Spencer on ITV Granada Reports

John Spencer on BBC Flog It

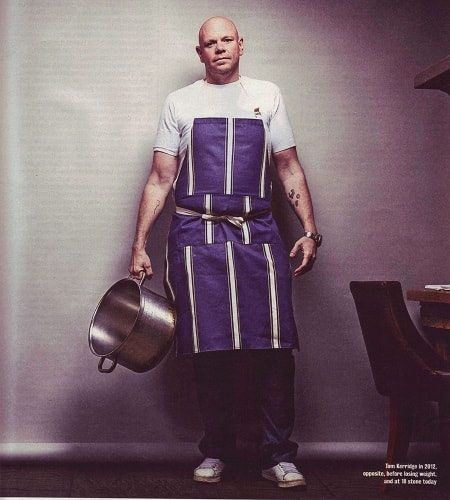

Tom Kerridge Modelling JST Woven Fabric

Our Environmental Commitments

It’s becoming increasingly import for your customers and end-users to have transparency on where their products are made, we invite our customers to visit or Lancashire mill to see first-hand the operations within our weaving facility.